Service description

Construction of halls and steel structures

Our steel halls are characterized by a flexible internal layout that allows you to easily adapt the space to the customer’s needs.

Steel halls are a solution that is gaining more and more popularity among entrepreneurs looking for durable, functional and, above all, quick to implement industrial facilities. Our company specializes in the design, production and assembly of steel halls for the needs of various industries and industries.

Our steel halls are characterized by a solid structure, load resistance and the ability to adapt to the various needs and requirements of our customers. We are able to make steel halls of various sizes, shapes and applications.

Types of steel halls that we offer:

- Industrial halls – characterized by large open spaces and high ceilings, which allows for the storage and production of various industrial elements.

- Warehouse halls – used for storing various types of goods.

- Sports halls – made of durable materials that ensure the safety of users.

- Agricultural halls – used for storage and production of various agricultural products.

In our company’s offer you will also find:

- Designs of steel halls, made individually for the client’s requirements, taking into account the specificity of the given area and technical requirements.

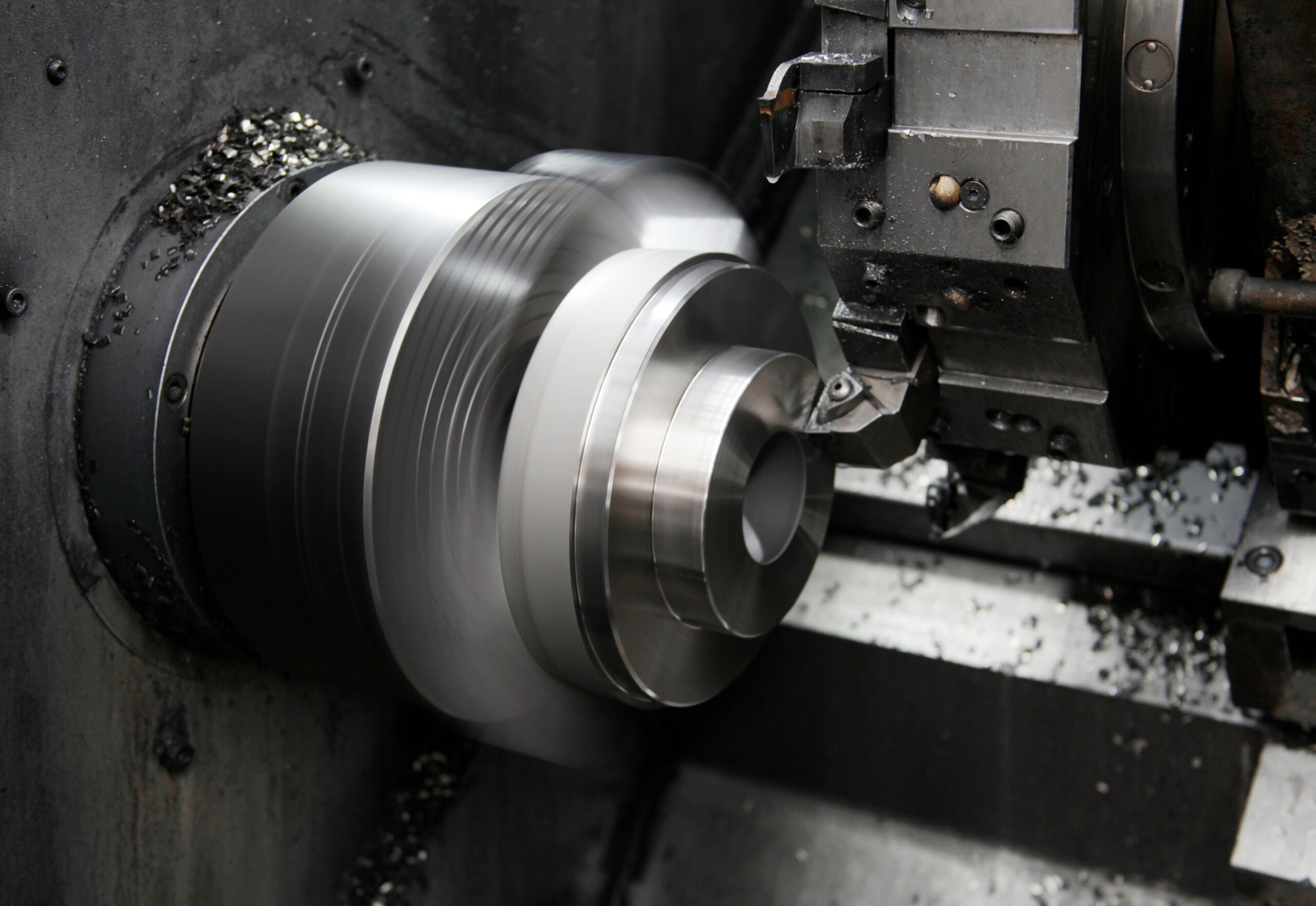

- Production of steel halls, made of the best materials, guaranteeing a long service life of the facility.

- Assembly of steel halls, carried out by experienced professionals, using professional equipment and tools.

- Modernization and extension of existing steel halls.

In addition, our company also offers a full range of additional services, such as: design, execution and installation of ventilation, air-conditioning and heating systems, painting of steel structures, execution of industrial floors and many others.

Construction process

A properly designed and built hall will ensure functional and safe working conditions, as well as contribute to effective warehouse and logistics management

Planning

The first step in the construction of a steel, warehouse or logistics hall is to determine the customer’s requirements and carefully plan the construction. At this stage, designers develop appropriate solutions tailored to the specifics of a given investment.

Projects

Based on the customer’s needs and the specificity of a given area, designers create a project that will take into account the requirements regarding the area, height, spatial layout and specification of materials from which the hall will be made.

Assembly of the steel structure

This is one of the key phases of building the hall. The structure must be well designed, solid and resistant to loads. Assembly of the structure is carried out by specialists who have appropriate qualifications and experience.

Interior finishing

At this stage, the interior of the hall is finished. Doors, windows, ventilation systems, lighting and electrical installations are installed.

Testing and acceptance

After the construction of a steel, warehouse or logistics hall is completed, tests and acceptance are carried out to ensure that all equipment is working properly and is safe to use.

See for yourself how many benefits a steel hall can bring

FAQ

Frequently

asked questions

What materials are used to build steel halls?

For the construction of steel halls, mainly structural steel, roofing, thermal insulation and finishing elements are used.

What are the advantages of building steel halls?

The advantages of building steel halls include: quick and easy assembly, low production costs, high structural strength, the possibility of easy expansion, as well as the possibility of using recycled materials.

How long does it take to build a steel hall?

The construction time of a steel hall depends on many factors, such as the size and complexity of the structure, the availability of materials, weather conditions, etc. Typically, the construction of a steel hall takes from several weeks to several months.

What factors affect the cost of building a steel hall?

The costs of building a steel hall depend on many factors, such as the size and complexity of the structure, the materials used, additional equipment (e.g. ventilation, lighting), transport and assembly costs, as well as location and ground conditions.

Is it possible to easily expand a steel hall?

Yes, one of the advantages of steel halls is the ease of expansion. The construction of the steel hall allows the addition of further sections or elements without the need to demolish the existing part.

What are the possible roofing options for a steel hall?

Possible roofing options for a steel hall include: trapezoidal sheet, polycarbonate sheets, sheets for mineral topping, bitumen tiles, etc.

Services