Service description

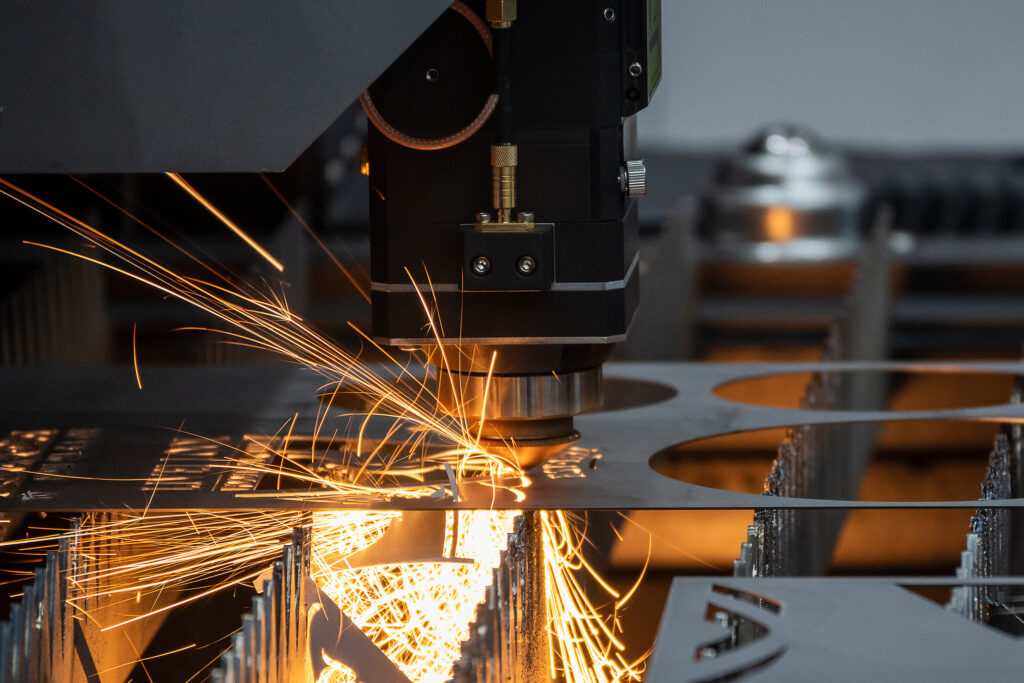

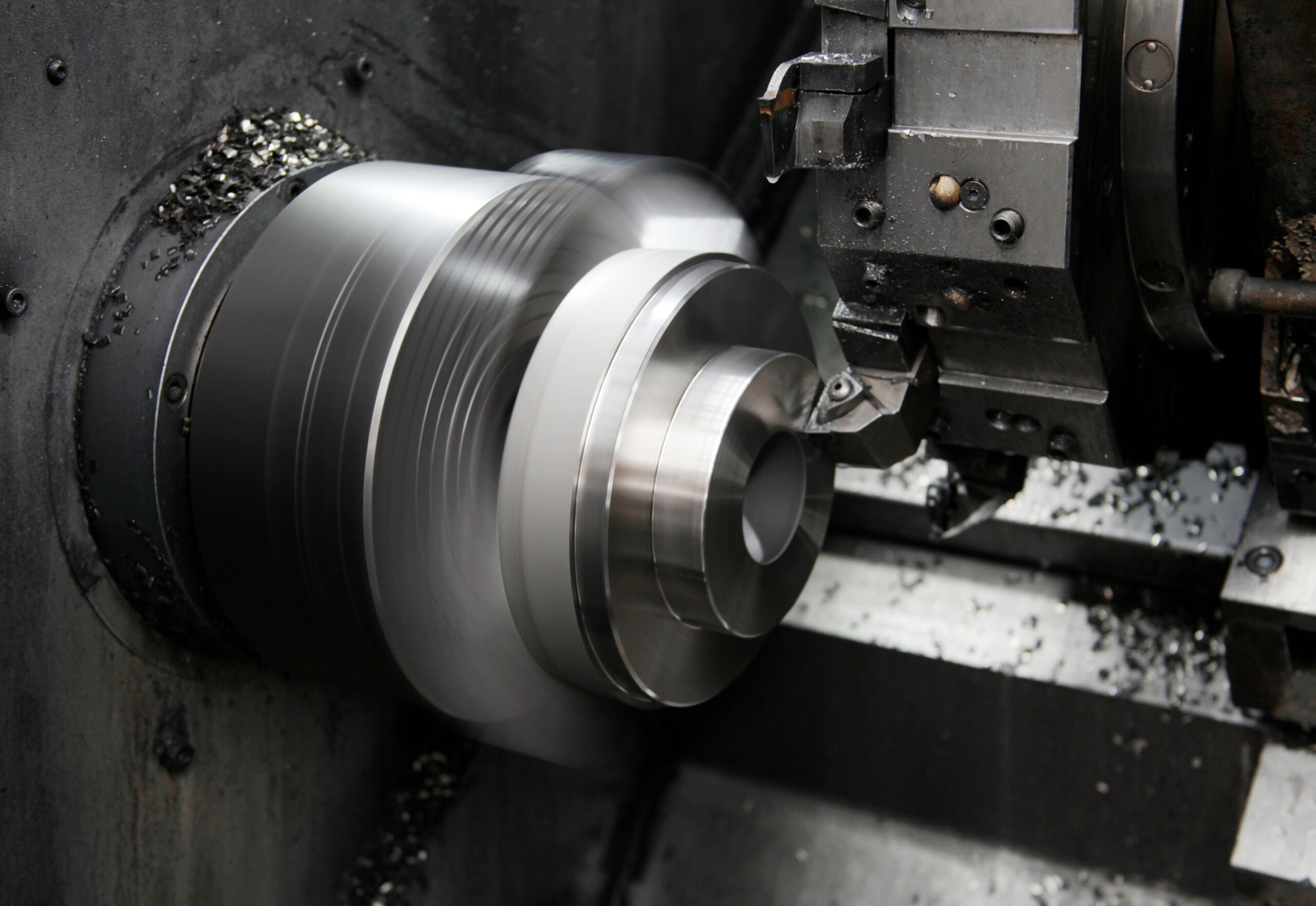

We use the best tools and materials, which allows us to achieve maximum precision and durability of our products

Our GEKA punching services include various types of machining including cutting, perforating, bending, hole punching, threading and much more. We can also make complex shapes and patterns according to the customer’s design.

Thanks to modern technologies and GEKA machines, we are able to perform even very difficult and complex projects with the highest precision. We also offer fast delivery times, which allows us to meet the expectations of even the most demanding customers.

Our offer is addressed to customers from various industries and industrial sectors. We cooperate with companies from the automotive, machine, construction, electronic and medical industries.

All our services are performed in accordance with the highest quality standards and in compliance with the highest occupational safety standards. Our qualified staff is ready to implement even the most demanding projects.

Professional punching services on GEKA mechines

FAQ

Frequently

asked questions

What is punching on Geka machines?

Punching on Geka machines is a process of cutting shapes and holes in sheet metal and other flat materials using a specialized Geka punching machine.

What are the main advantages of punching on Geka machines?

The main advantages of punching on Geka machines include: high precision, repeatability and speed of the process, as well as the ability to process various flat materials, such as steel, aluminum, brass or copper.

What are the most common shapes when punching on Geka machines?

The most frequently performed shapes when punching on Geka machines are e.g. circles, squares, rectangles, triangles, circles, as well as holes of various shapes and sizes.

Is punching on Geka machines expensive?

The cost of punching on Geka machines depends on many factors, such as the type of material, the size of the elements, the number of pieces to be produced, as well as the complexity of the shape and the type of tools used. However, compared to other punching methods, Geka punching is usually more expensive, but it produces high precision and repeatable parts.

Services