Service description

The sheet metal bevelling service allows you to obtain elements with higher aesthetics and functionality

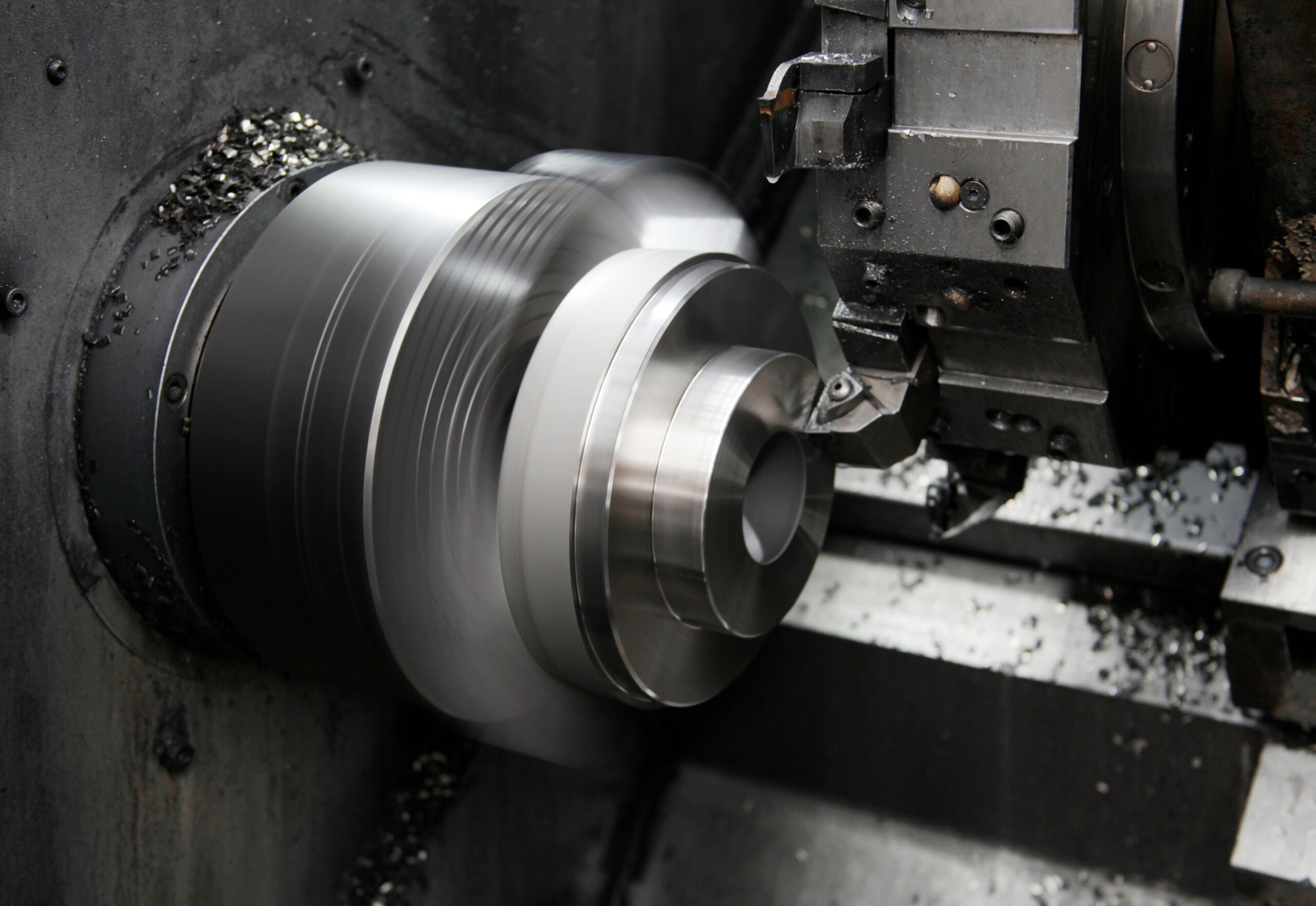

The sheet metal bevelling service is the process of converting flat sheet metal into the desired shape by cutting the edge at an angle to obtain a beveled edge on the sheet metal. Sheet metal bevelling is used in many applications including furniture, construction, automotive and many others.

The sheet metal beveling process consists in setting the sheet metal in a special beveling machine, where it is moved along the cut line at the right angle. After the edge is cut at an angle, the sheet is polished to a smooth, even surface.

The beveled edge of the sheet can have many applications, such as hiding the connection of two elements, facilitating assembly or improving the aesthetics of the element. Thanks to the use of appropriate technology and the experience of the staff, the sheet metal beveling service allows you to obtain elements of excellent quality and repeatability of dimensions.

Are you interested in the sheet beveling service?

FAQ

Frequently

asked questions

What is plate bevelling?

Sheet metal bevelling involves cutting the sheet metal at an angle, creating a beveled edge.

What are the most commonly used sheet metal beveling tools?

The most commonly used tools for beveling sheet metal are angle grinders, cutters, sheet metal shears and special beveling machines.

What are the most important factors affecting the quality of sheet bevelling?

The most important factors affecting the quality of sheet metal beveling include: proper selection of beveling tools and parameters, sheet thickness, material purity, surface quality and operator skills.

What are the most common problems that can occur when beveling sheet metal?

The most common problems that can occur when bevelling sheet metal include: uneven bevelling, cracks or distortion of the material, and problems with the exact positioning of the material.

Services